Dry baked goods

STICKS

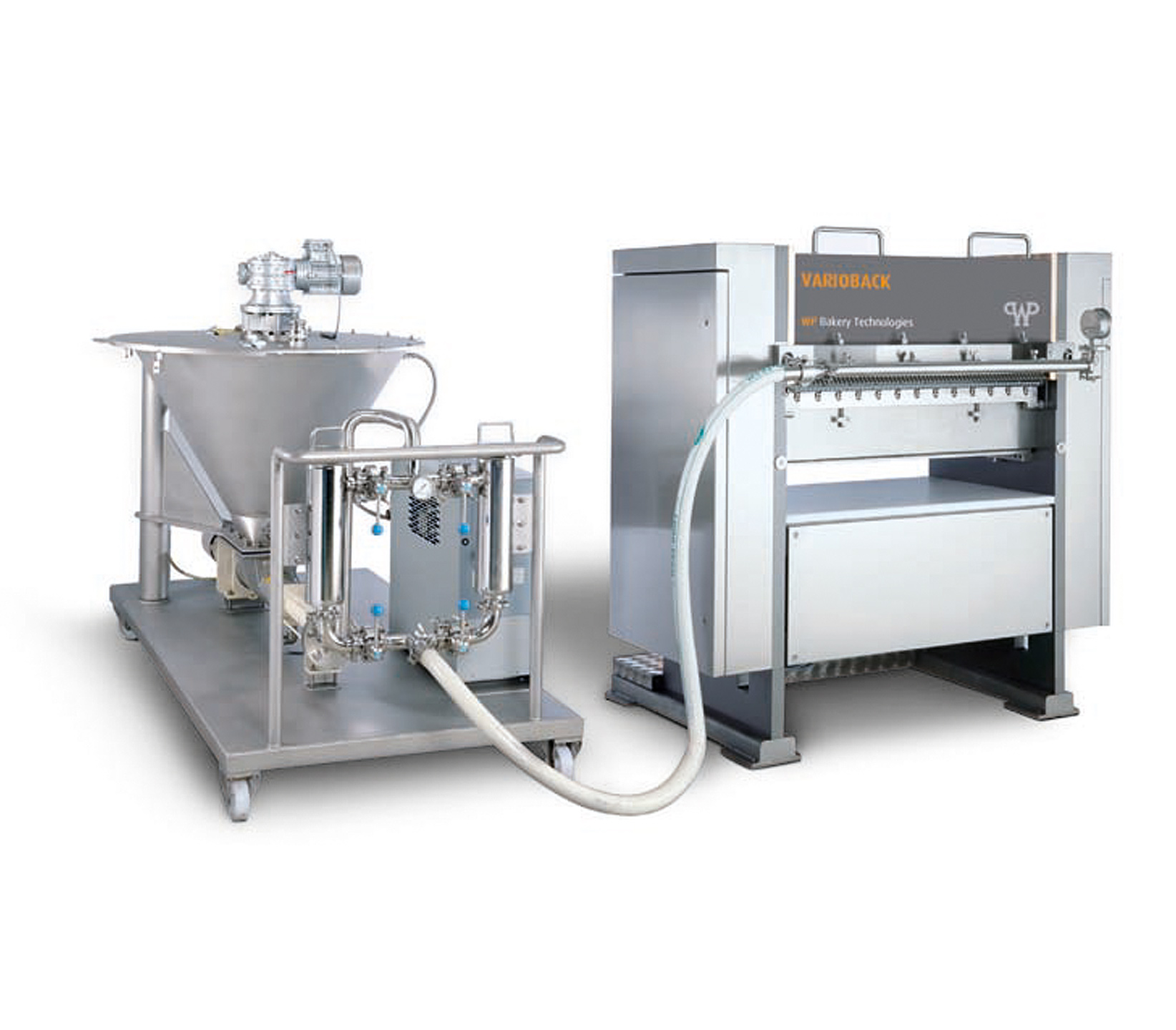

PRESS SP

- High product quality

- Short payback period

- High availability

The principle: variable and customised

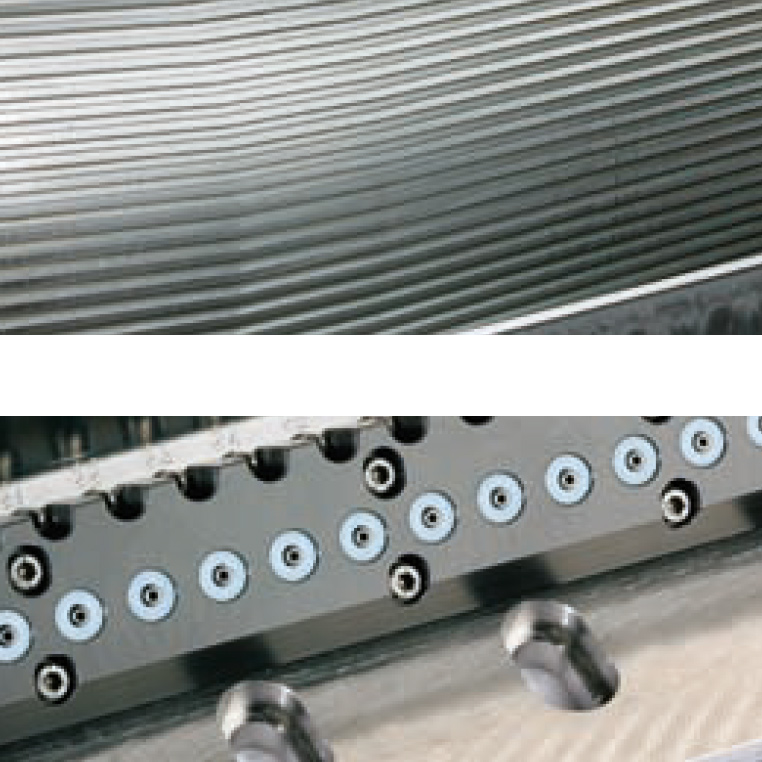

Whether its classic, filled or twisted sticks: the SP STICKS PRESS is extremely flexible and can be perfectly adapted to customised requirements. With the SP STICKS PRESS, you can produce various product types because a range of product diameters and shapes can be achieved by using appropriate nozzle geometries.

Thanks to interchangeable nozzle bars, the retooling times to other products are reduced to a minimum. The SP STICKS PRESS can be combined with components for manufacturing crackers and and moulded-biscuit products, such as cocktail pretzels. The trend in the pretzel-type sector are savoury fillings such as peanut, chilli and tomato mixtures and chocolate fillings top the list of sweet flavours.

The dough is fed into the hopper of the machine via a dough proportioning hopper. A corrugated roller conveys the dough into the pressure chamber. The dough is pressed into thin, endless strands of dough through nozzles that are distributed over the entire width of the machine.

The speed of the corrugated roller can be regulated via a frequency-controlled three-phase motor so that the exit speed of the strands of dough from the nozzles is matched to the speed of the oven belt.

High performance, maximum benefits and modular options

The SP STICKS PRESS is intended for manufacturing sticks with diameters of approx. 3 to 5 mm. The smallest possible diameter for filled sticks is 6 mm. The dough exit speed is up to approx 14 metres/minute. A working width of 1,200 mm thus achieves an hourly output of max. 400 kg of baked sticks. The exact output depends on the individual recipe, the diameter of the sticks and the oven size.

- Smart control:

- Touch-Screen Operator Panel, Siemens SPS

- Energy efficiency:

- Efficiency class IE2 for drive motors

- Hygiene:

- wash down

- easy access

- stainless steel

Dough exit speed

up to 14 m/min

Capacity

max. 400 kg of baked sticks/h

Optionen

- Operator panel for operating and monitoring the sP sticks press with lye bath

- Automatic dough feeding to the SP STICKS PRESS notching / cutting device

- Salt sprinkler with transverse discharging worm for returning excessive salt

- Biscuit-moulding machine for combined production of sticks and pretzels

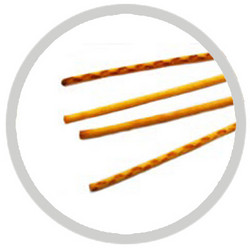

Whether classic, filled

or twisted sticks

Customized shapes are possible on request.

Classic Sticks

Marmelade Sticks

Schokolade Sticks