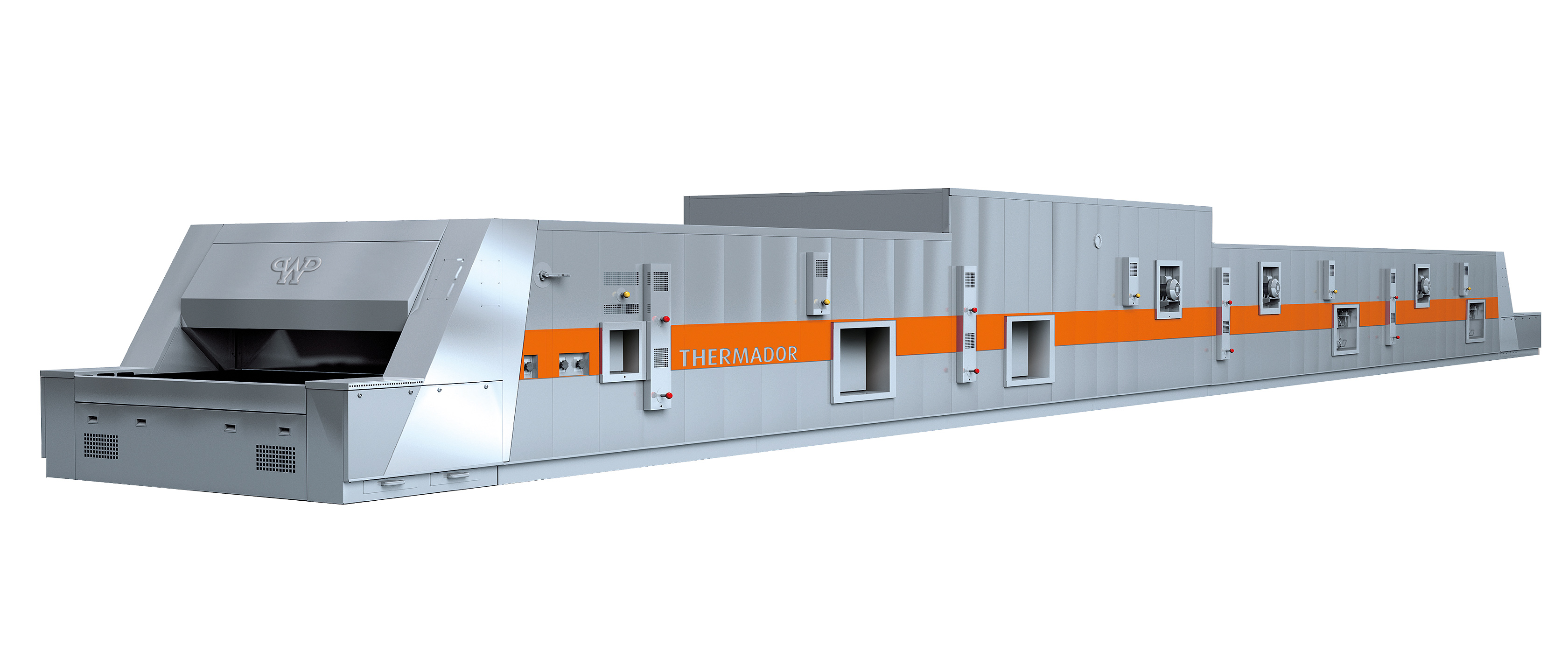

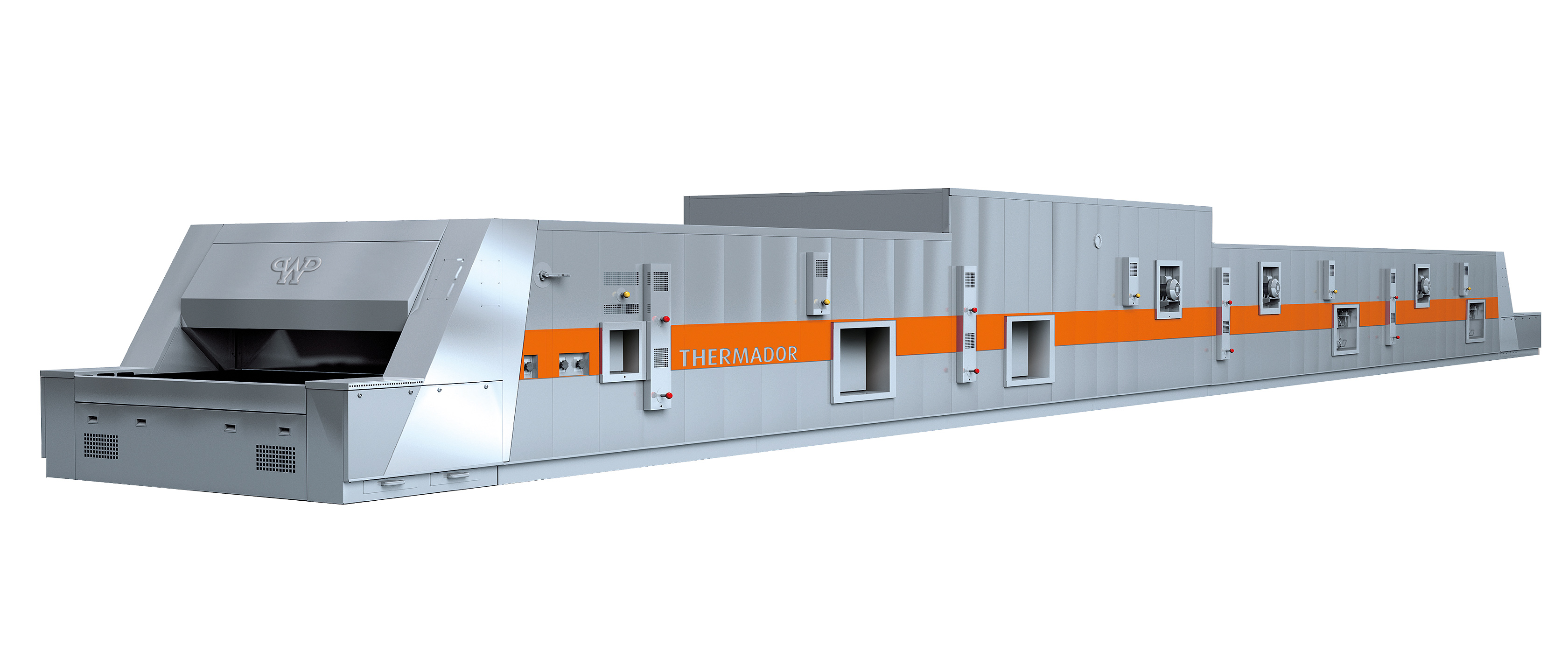

Continuous tunnel oven

THERMADOR

- continuous production

- most advanced baking technology

- high economic efficiency

The tunnel oven for

continuous baking

Premium quality in the baking process according to the requirements of each product requires individual temperature, heat transfer and humidity profiles. The WP solution for perfect baking results with optimised energy use is called: THERMADOR. The reliable tunnel oven for continuous production of the entire product range combines modern baking technology and high economic efficiency with reliability and durability.

INDIRECT HEATING

Perfect baking results are achieved due to the closed ZYKLOTHERM heating gas circulation system. This is an indirect heating system, which means that the heating gases are separated from the baking chamber and do not come into contact with the baked goods. Heat is transferred to the baked goods via radiation, convection and heat conduction. Each control zone can be regulated independently by means of top and bottom heat.

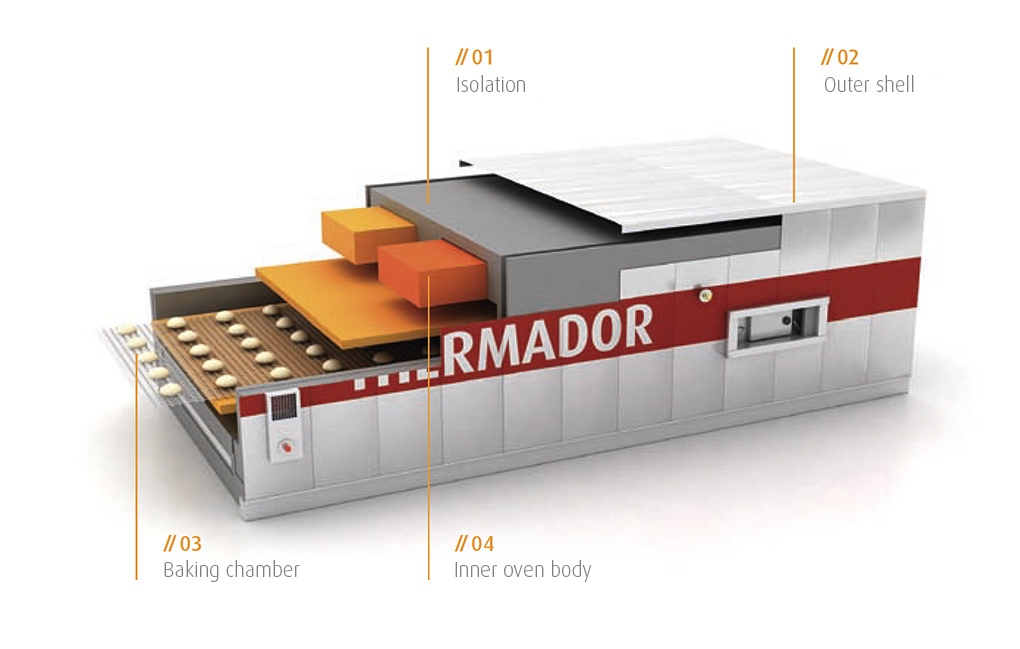

MODULARITY

The unique modular design of the THERMADOR furnace system allows individual oven configurations as well as a freely combinable zone arrangement of Zyklotherm, Duotherm, Infrared and Quattro:

- closely stepped modular system from 10.5 to 60 m for a product-related zone arrangement

- Flexibly combinable and universal

HYGIENE

The oven systems meet the hygiene requirements according to DIN EN 1672-2: extra-large removable, divided cleaning and viewing doors as well as self-cleaning function of the mesh belt. No combustion gases in the baking chamber.

INFRARED TECHNOLOGY SPECTRA

With this technology, the heat radiation is shifted into the infrared range. The baked product reaches the required core temperature faster, which shortens baking times and saves energy. In addition, undesired surface browning is avoided, the product retains a higher moisture content and has improved volume and optimised taste characteristics as well as longer freshness times. All oven types can be equipped with this technology.

AFTER SALES

Ease of maintenance: Highest quality, solid design and low maintenance requirements ensure high availability. Remote maintenance is possible.

INDIVIDUAL OVEN CONFIGURATION

The control zone configuration allows the oven to be adapted to individual product requirements and the optimum baking curve of the product. The THERMADOR oven system offers very fine gradation options so that temperature and humidity affect the baked product to the required degree at the right time in the baking process.

High energy utilisation - up to 35 % less energy consumption

Since energy costs nowadays account for a steadily increasing proportion of the total production costs for baked goods, Werner & Pfleiderer has also developed concepts in this area that reduce energy consumption while maintaining reproducible premium quality, thus saving energy costs:

High performance, maximum benefits and modular options

Rising staff costs and competitive pressure demand automated solutions. That is why the THERMADOR is equipped with both semi-automatic and fully automatic control. Werner & Pfleiderer relies on the latest digital control technology. User-friendly touchscreen panel - easy comprehension and logic to avoid operating errors.

- Energy optimisation

- Since energy costs nowadays account for a steadily increasing proportion of the total production costs for baked goods, Werner & Pfleiderer has also developed concepts in this area that reduce energy consumption while maintaining reproducible premium quality, thus saving energy costs:

- Process control and monitoring

- No surface losses due to optimal module design and highly efficient thermal insulation

- Use of energy-efficient materials

- More powerful DUO fans

- Quattro system

- Controlled steam quantity supply according to individual requirements

- Low exhaust gas temperatures

- Short baking times

- Since energy costs nowadays account for a steadily increasing proportion of the total production costs for baked goods, Werner & Pfleiderer has also developed concepts in this area that reduce energy consumption while maintaining reproducible premium quality, thus saving energy costs:

- Process optimised:

- Semi- or fully automatic control and regulation of:

- Baking time

- Heating gas temperature / zone temperatures (according to top and bottom heat)

- Steam and moisture quantity

- Radiant wall temperatures

- Automatic changeover to new process data in the event of a change of type

- Gap detection and automatic readjustment of zones for top and bottom heat

- Speed & direction of rotation of the DUO fans

- The automatic control of the DUO fans prevents overheating of the oven in case of under-utilisation.

- Heating gas and steam sliders are electrically driven and integrated into the control system

- Semi- or fully automatic control and regulation of:

- Safe:

- Zero-error technology: the system is self-regulating

- 99 different recipes can be stored

- Display of all operating data and temperature profiles across all oven zones

- Reproducibility and product traceability

- Display of all operating and fault messages

- Extensive service level integrated in operator level for commissioning, service and maintenance without additional programming device

- Remote diagnosis via internet and telephone

Conveyor width:

2.000 mm

2.500 mm

3.000 mm

3.300 mm

3.750 mm

4.000 mm*

*Specifications do not apply to Stone and Grid

Useful width:

1.950 mm

2.450 mm

2.950 mm

3.250 mm

3.700 mm

3.950 mm

Baking compartment length:

10.500 – 60.000 mm**

**Combination of baking chamber width and length is dependent on the baking load carrier transport

Baking compartment height:

260 mm

Heating medium:

Natural gas, light fuel oil or electricity

Conveyor load:

30 – 90 kg/m² (higher load on request)

Conveyor design:

50 kg/m² (higher load on request)

Options

- THERMADOR with meshed belt

- THERMADOR Stone with stone plate conveyor

- THERMADOR Grid

Industrial premium quality through gentle baking

Kaiser rolls

Hamburger buns

Ciabatta breads

Panettone

Tin loafs

Mixed breads